Stamped heat sinks are usually light-gauge stampings of aluminum. Because they are stamped from a sheet of metal, these heat sinks have low fin density. The mounting surface is usually not flat, requiring high mounting torque or a conformable interface material.

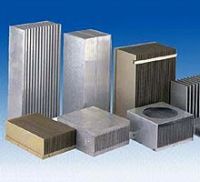

Stamped heat sinks are usually light-gauge stampings of aluminum. Because they are stamped from a sheet of metal, these heat sinks have low fin density. The mounting surface is usually not flat, requiring high mounting torque or a conformable interface material. Extruded heat sinks are either bidirectional or omnidirectional. Bidirectional sinks let air flow either way along the extrusion direction. Omnidirectional sinks let air pass through the heat sink at any angle, usually because the manufacturer crosscuts the heat sink. An extruded heat sink has a 2-D cross section, and the heat sinks typically come in 8-ft lengths. The heat-sink vendor buys these lengths from an extruder and cuts them to length, adding holes and other features as needed. Omnidirectional heat sinks start out as extrusions, and crosscut saws make the fins in the other direction. The result is a pin-fin grid arrangement. The crosscut heat sink in 45 degree angle flow has about 25% higher temperature rise than its lined-up flow twin. One advantage of the omnidirectional type is that the pin-fin arrangement allows for more precise positioning of the heat sink using clips.

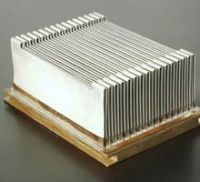

Extruded heat sinks are either bidirectional or omnidirectional. Bidirectional sinks let air flow either way along the extrusion direction. Omnidirectional sinks let air pass through the heat sink at any angle, usually because the manufacturer crosscuts the heat sink. An extruded heat sink has a 2-D cross section, and the heat sinks typically come in 8-ft lengths. The heat-sink vendor buys these lengths from an extruder and cuts them to length, adding holes and other features as needed. Omnidirectional heat sinks start out as extrusions, and crosscut saws make the fins in the other direction. The result is a pin-fin grid arrangement. The crosscut heat sink in 45 degree angle flow has about 25% higher temperature rise than its lined-up flow twin. One advantage of the omnidirectional type is that the pin-fin arrangement allows for more precise positioning of the heat sink using clips.Another important characteristic of an extruded heat sink is its aspect ratio. A high aspect ratio leads to a better-performing heat sink. The aspect ratio of an extrusion is roughly the fin height divided by the fin spacing. Typical heat sinks have a 3:1 to 5:1 aspect ratio. Extrusions can go up to an 8:1 or 10:1 ratio. Generally, fin heights are limited to 3 in. or less; heat-sink widths range up to 18 in.

Bonded-fin heat sinks are newer than the stamped and extruded types. In a bonded-fin heat sink, an extruded aluminum base holds plate fins in place, usually with an epoxy adhesive. Typical fin aspect ratios are around 10 or more; thus, if you can move enough air through these heat sinks, they perform well. However, moving enough air is a big if; most air movers move less air when confronted with a large impedance. Also, the fin material sometimes has lower thermal conductivity than does extruded aluminum.

Bonded-fin heat sinks are newer than the stamped and extruded types. In a bonded-fin heat sink, an extruded aluminum base holds plate fins in place, usually with an epoxy adhesive. Typical fin aspect ratios are around 10 or more; thus, if you can move enough air through these heat sinks, they perform well. However, moving enough air is a big if; most air movers move less air when confronted with a large impedance. Also, the fin material sometimes has lower thermal conductivity than does extruded aluminum.So, in many applications, the performance of a bonded-fin heat sink compares with that of a good extruded heat sink. The advantage of the bonded fin's construction method is that its heat-sink base can hold much better dimensional tolerances, and, if the heat sink is very wide, the bonded fin's cost is comparable with that of an extrusion. In addition, fins taller than 3 in. are available, and their height can vary along the length of the heat sink. This height variation can even extend to leaving gaps in the fins where fins are not needed. In this case, bonded-fin technology can offer potential savings over an extrusion because it isn't necessary to remove any fin material.

Convoluted fins are thin folded fins. Add a base plate and a shroud for mechanical stability, and you have a lightweight heatsink. These heat sinks pack a lot of heat-transfer surface area into a small space, but at the price of air-pressure drop. You need to duct the airflow into the heat sink to get good performance from the sink. As with the bonded fins, the fan cannot move as much volume because of the pressure drop. A typical fan curve for a convoluted fin heatsink will show that as pressure increases, airflow decreases. Another consideration is that the convoluted fins don't perform well in natural convection, which is a potential problem if the system fan fails.

Convoluted fins are thin folded fins. Add a base plate and a shroud for mechanical stability, and you have a lightweight heatsink. These heat sinks pack a lot of heat-transfer surface area into a small space, but at the price of air-pressure drop. You need to duct the airflow into the heat sink to get good performance from the sink. As with the bonded fins, the fan cannot move as much volume because of the pressure drop. A typical fan curve for a convoluted fin heatsink will show that as pressure increases, airflow decreases. Another consideration is that the convoluted fins don't perform well in natural convection, which is a potential problem if the system fan fails.

Zipper fin heatsinks are built using single sheets of formed metals, usually aluminum or copper metal, that are interlocked together mechanically. The resulting fin pack assembly allows engineers to design heatsinks with very high aspect ratios. Zipper fin heatsink can serve as an alternatives to folded fin heatsinks since their high thermal performance is equal to or slightly better than their folded fin heatsink counterpart. Zipper fin heatsinks have several other advantages over folded fin heatsinks, including lower tooling costs, faster lead times, the ability to use different metals within the fin pack, and the ability to design more complex heatsinks.

A fan sink is a heat sink with a fan mounted on it. For ICs, the fan usually mounts on top. For the fan to perform at its rated capacity, leave some headroom for air supply to the fan (check the manufacturer's specifications.) A fan sink can help in situations in which you have insufficient local airflow. However, if you can put your fan in a place where there is fresh, cool air, do so. This air is better than potentially recirculated warm air. If you are buying a fan sink, get the fan with the smallest hub diameter. Air cannot go under the hub, so the hub heats up. This hot spot is usually in the center, right over the chip. The fan hub heats, reducing the fan's life expectancy. So, don't skimp on the fan cost: Buy the best. Also, make sure the system has an overtemperature sensor.

A fan sink is a heat sink with a fan mounted on it. For ICs, the fan usually mounts on top. For the fan to perform at its rated capacity, leave some headroom for air supply to the fan (check the manufacturer's specifications.) A fan sink can help in situations in which you have insufficient local airflow. However, if you can put your fan in a place where there is fresh, cool air, do so. This air is better than potentially recirculated warm air. If you are buying a fan sink, get the fan with the smallest hub diameter. Air cannot go under the hub, so the hub heats up. This hot spot is usually in the center, right over the chip. The fan hub heats, reducing the fan's life expectancy. So, don't skimp on the fan cost: Buy the best. Also, make sure the system has an overtemperature sensor.The main purpose of an interface material is to fill the tiny air gaps between two dry surfaces. The flatter and smoother the surfaces, the thinner and softer the interface material required to fill the gaps. Because perfectly smooth and flat surfaces don't exist, you almost always get better performance from an interface material than from a bare metal-to-metal interface. Key characteristics of an interface material are thermal performance, compliance, adhesive properties, and reworkability. In some cases, electrical conductivity is also important. The materials include thermal compounds, solid-filled polymers, epoxies, and tapes. If your application is critical, weigh the costs of applying the material against the thermal performance you need. For example, if you must remove the heat sink from the component, choose a solid material. To get the best performance with the lightest weight, select a thermal compound. If the surface on which the heat sink must sit is uneven, a thicker conformable polymer is necessary to make up for height variations. For best performance, choose a polymer filled with a thermally conductive powder (alumina or metal, for example). Finally, if you use a clip, material adhesive properties are unimportant. Whatever material you choose, make sure that you can install it without air bubbles, because the point of using an interface material is to eliminate air pockets. Some materials are available preinstalled from heat-sink vendors, saving you the cost of dispensing or cutting to size and then applying it in your shop.